AEInnova, a leading European innovator in autonomous sensors, has developed cutting-edge IoT solutions that use energy harvesting technology to power devices. The company is focused on creating heat-powered, battery-less sensors specifically designed for Industry 4.0 and the Oil&Gas sectors.

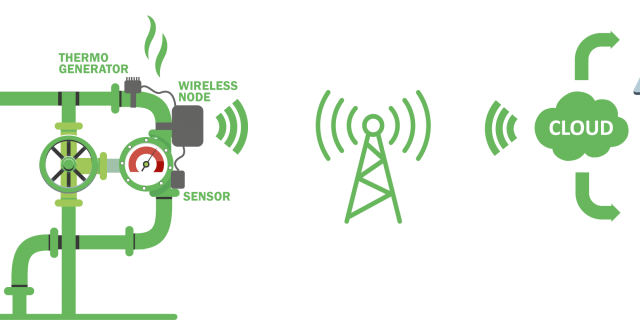

AEInnova's flagship development is the first NET-ZERO, battery-less, maintenance-free, heat powered IoT system for machinery predictive maintenance and steam leak detection. These sensors monitor real-time data such as vibrations, temperatures, and steam, and communicate with the cloud through long-range wireless protocols like LoRaWAN and NB-IOT.

Additionally, it is certified for operation in explosive environments (ATEX/IECEX). The Spanish company’s achievements have earned it 31 international awards, including two from the United Nations, as well as recognition from DENA, IoT World Congress, and the IoT World Cup.

Wireless and Batteryless IoT solution with full monitoring system.

InduEye is the first commercial NETZERO ATEX heat-powered, batteryless, maintenance-free and long-range wireless iIoT solution that overcomes the traditional problems of IoT implementation in Industry 4.0.

InduEye Vibro and Vindueye Thermo, allow monitoring vibrations and temperatures of your processes. They send data every few minutes up to 14km of distance (using LoRaWAN, and coming NB-IOT/LTE-M) requiring very few investments in wireless infrastructure.

InduEye leaks, being at the end stage of development, will allow the detection of leaks in steam traps and valves. This solution incorporates temperature and ultrasound sensors.

All devices incorporates Edge computing technologies to pre-process data and save cloud computing costs.

Addressing the industry energy efficiency

Big industry loses up to 65% of energy as waste heat. Only in Europe, we are losing up to 20% of the annual energy needs as waste heat.

The WHRU uses an awarded technology capable to convert waste heat into clean CO2 negative energy. This solution, in its last state of development, is capable to generate electricity from hot surfaces allowing injecting it into the electricity network for self-consumption, promoting a circular economy, and reducing CO2 royalty payments.

For more information visit the project website life.aeinnova.com

INDUSTRY 4.0 IS HERE

Poor maintenance strategies can reduce a plant’s overall productive capacity between 5 and 20 percent. Recent studies also show that unplanned downtime costs industrial manufacturers an estimated $50 billion each year.

AEInnova is also partnering with the CBC Group in Japan.

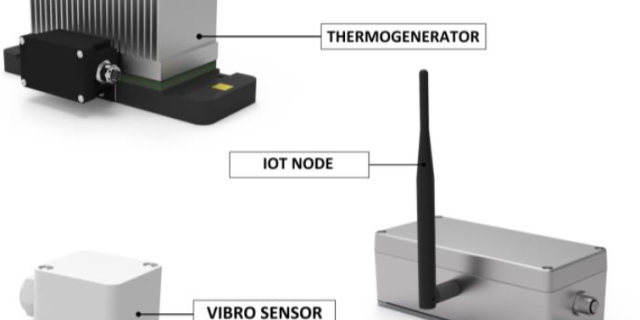

High-performance sensing system Indu-Eye LoRa Vibro v1.0 powered by Heat. Complete monitoring solution by three modules.

Main features:

Battery-less: Self powered by heat.

Maintenance free: Autonomous solution, increasing productivity and profits.

Wireless: use of LoRa Protocol, data is generated and processed into the device and sent to a LoRaWAN gateway.

Cost-effective infrastructure: Up to 1.000 IoT devices in a 2 km radius (LoRaWAN gateway).

Visualization at Cloud through: DAEVIS dashboard or a third-part SCADA platform.

Reduction of 90% cloud computing costs: Thanks to edge-computing in the iIoT device. o High-performance vibration: Monitoring with a 3-axis accelerometer.

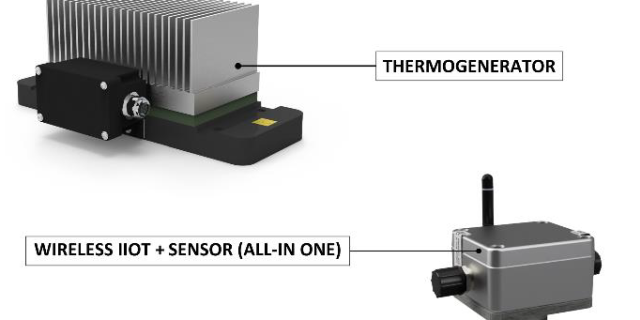

High-performance sensing system InduEye LoRa Vibro v1.3 powered by Heat.

Main Features:

Battery-less: Self powered by heat.

Maintenance free: Autonomous work, no battery dependency.

Wireless: use of LoRaWAN Protocol, data is generated and processed into the device and sent to a standard LoRaWAN gateway.

Low infrastructure needs: Up to 1.000 IoT devices in a 2 km radius (LoRaWAN gateway).

Visualization of data through: DAEVIS dashboard or a third-part SCADA platform.

Reduction of 90% cloud computing costs: Thanks to edge-computing in the iIoT device.

High-performance vibration: Monitoring with a 3-axis accelerometer + temperature. o Optional: Addition of temperature sensor (PT100, PT1000...)

Have a look at some companies that already benefit from our support. This is what Japanese stakeholders would see in Japanese.